A significant part of the Medical Physicist's time (probably not only in our department) is dedicated to various quality assurance checks. We are currently doing regular constancy checks for the linacs, the simulator, the afterloader, the treatment planning systems and a C-arm.

In the old days (1996+), the protocols were basically text- or spreadsheet-templates, which were printed and filled out by hand. Later, we introduced online-spreadsheet-documents. These were filled out on the PC and printed/signed after completion. Although the online-protocols gave the possibility to include basic calculations like averaging or calculating the deviation from a baseline, the documents were still unlinked, so there was no possibility to correldate data or make a trend analysis.

Another drawback of the online-protocols was the lack of computers inside treatment rooms: when doing mechanical checks, one would first have to write down the results on paper, leave the treatment room and fill out the online-form on the nearest PC, usually located in the control room. For this problem, a PDA with the right software was the elegant solution (see below).

iCheck is our Microsoft® Access 2000-database which currently covers the checks displayed in the main screen (Fig.1), after the user logs in (iCheck is password protected). In addition to the linac, simulator and TPS checks, there are links to our hand-calculation (Gy->MU) and plan-verification (MU->Gy) software ("PHI v3.6 Beta") and to an electron calculation database (which also contains patient information from the Varis database). The "Absolutdosimetrie" link goes to an Excel sheet for absolute dosimetry and linac MU-calibration. The "Absolutdosimetrie Statistik" gives an overview of all the MU calibrations performed on the linacs in the past.

|

Fig.1: iCheck main screen. |

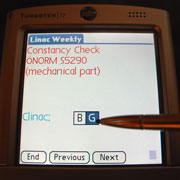

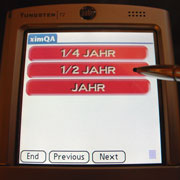

For the linacs, we have constancy checks on a daily, weekly, monthly, quarterly and half-yearly schedule. The yearly check is split up in two parts, and is completed during the half-yearly checks. For this purpose, the linac is offline for two full days.

The Simulator has a similar schedule, except that there is no daily check.

The standards which are the basis for our quality assurance programs are updated from time to time. Currently, we are using the following Austrian standards, issued by the Austrian Standards Institute:

| Linac | ONORM S5290 (issue 1.11.2005) |

| Simulator | ONORM S5294 (issue 1.2.2004) |

| Treatment Planning Systems | ONORM S5295 (issue 1.8.2004) |

| HDR Afterloader | ONORM S5292 (issue 1.5.1996) |

| C-Arm | home made protocol |

The introduction of iCheck in Dec2003 also improved the workflow (thus saving time), because it provides the user with a step-by-step to-do list. The weekly check on the linac has two main parts: the mechanical checks, where various mechanical parameters are assessed in the treatment room, and the dosimetric checks, where a certain QA phantom is used for dose measurements. The user may choose to start with the mechanical or the dosimetric part.

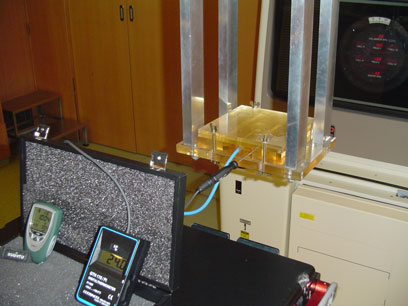

The weekly dosimetric check starts by setting up the equipment in the treatment room. Until recently, a Roos type plane parallel chamber was used for all weekly constancy measurements. The chamber is positioned at the central axis. For 4 and 6MeV Electrons, in order to get approximately to dmax, the acrylic block with the chamber is taken out of the gantry mount phantom shown below, and put on top of the top slab. A probe inside the phantom gives temperature readings, the displays are monitored with a video camera from the control room. This gantry mount phantom #1 (8SK1, shown in the photo) is currently being replaced by phantom #2 (SK2), which uses a Farmer chamber in the same setup for all energies.

|

Fig.2: Gantry mounted phantom #1, with Roos chamber, temperature and pressure sensors (click on most images to enlarge). |

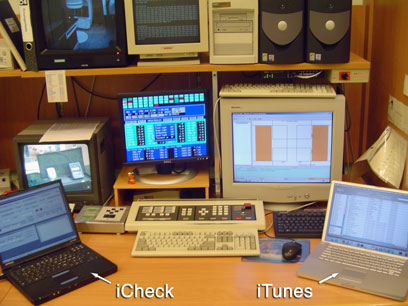

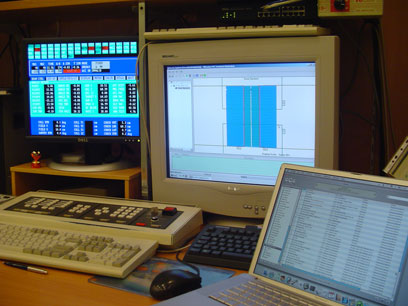

Photos and port images of SK2 can be seen here. The laptops (a physicist nowadays needs two of them) are set up in the control room, and iCheck is started.

|

|

Fig.3: Basic layout in the linac control room. |

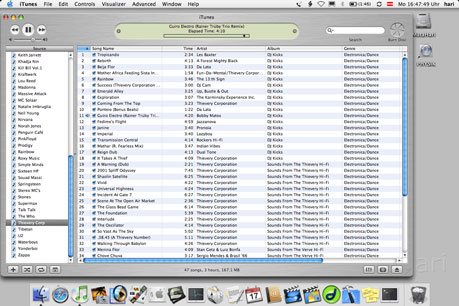

Fig.4: Choosing the right playlist for the check is essential. |

The user logs in and enters some basic parameters, which gets him to the main screen with the (optional) Unidos data acquisition board.

|

|

Fig.5: Selecting basic parameters, entering pressure and temperature |

Fig.6: Using the Unidos-Acquire Board speed up data acquisition |

Temperature and pressure can be changed any time, e.g. when the phantom gets slightly warmer. Dose data can be captured directly from the Unidos electrometer via RS232 interface and a VisualBasic module. With this functionality, the reading no longer has to be typed into the online-form manually (which took much longer and was source of errors). Now, when the "Acquire/ReStart"-button is pressed on the Acquisition board once, the electrometer reading is captured and a new measurement starts. During the measurement cycle, one has information on the current deviation from the baseline. Select measurements can be repeated, since each of the three measurements has its own "Acquire/ReStart"-button.

|

|

Fig.7: The dose measurement starts with 4MeV Electrons. Three times 100MU are delivered at dose rate 600 or 1000. |

Fig.8: Three independent Acquire/Restart buttons give more flexibility. |

Deviations are shown with a yellow background if larger than 1% and with a red background if larger than 2%. The Add-Ons covered by the check are "open field", EDW and DMLC.

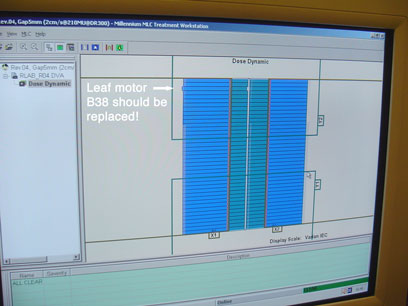

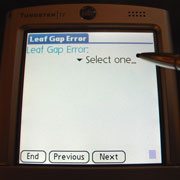

Some words on our DMLC checks. It is very simple and has two main goals: leaf motor performance and dose verification. To find out whether leaf motors should be replaced, I designed a simple DMLC treatment. All leaves slide from left to right and back four times, forming a 5mm wide sliding window. The jaws are 10x10cm. The MU are chosen such that all leaves move at 2cm/s. Delivering 210MU @ DR300 should be possible without any hold-offs. When all leaf motors are in good condition, DR400 is also possible without hold-offs, which corresponds to a leaf speed of 2.7cm/s.

|

|

Fig.11: The DMLC dose measurements check dose constancy and leaf performance. |

Fig.12: DMLC baseline is the average of a certain number of measurements over several months. |

DMLC dose is measured on the central axis. It should not deviate from the baseline by more that 2%. Basically this is to verify the setting of the Parameter "leaf gap error" in the MLC controller: if this parameter is changed by 10 (in units of 1/100mm), dose changes by 2% for the narrow sliding window. The following screenshots show a check where hold-offs occured, which were caused by the poor performance of leaf B38. This means that the leaf motor should be replaced within the next days, in order not to increase treatment time too much. It should be pointed out that the delivered dose will always be correct, because the beam pulses are instantly held off as long as a leaf is out of tolerance during delivery.

|

|

Fig.13: The DMLC check has to be simple but effective. |

Fig.14: Leaves that cannot hold the speed are easily identified. |

Currently, the long term analysis of data accumulated in the iCheck database is only possible for dose measurements. In principle, all data could be analysed, but we currently do not find this of much interest for mechanical parameters.

|

Fig.15: For analysis, a certain combination of phantom, energy and add-on has to be selected. |

|

|

Fig.16: This plot shows corrected readings and baseline independent of each other. |

Fig.17: The bar plot displays the deviation from the baseline in percent. |

|

|

Fig.20: For electrons, there is a higher variation of dose readings. |

Fig.21: Therefore, plus minus 2% are accepted. Action level is 3%. |

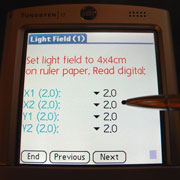

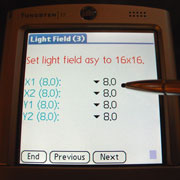

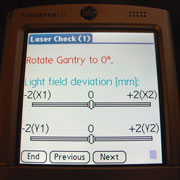

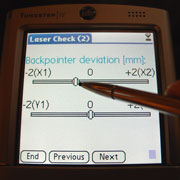

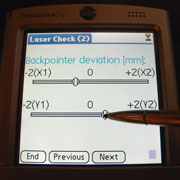

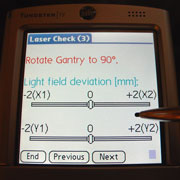

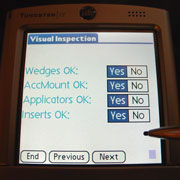

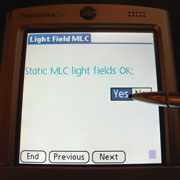

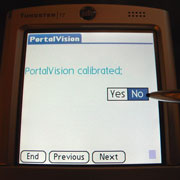

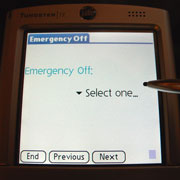

The mechanical part of the weekly check verifies the ODI readout, the size and position of light fields and backpointer, the static MLC light field and the integrity of mechanical equipment.

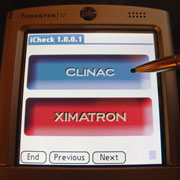

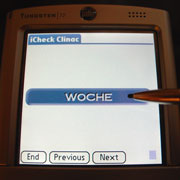

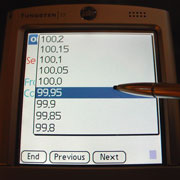

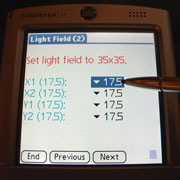

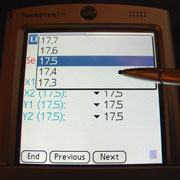

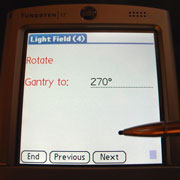

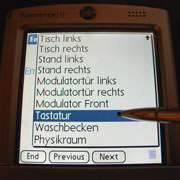

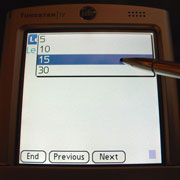

In order to avoid carrying a laptop to the treatment room, we found an elegant solution for the in-room data acquisition problem by using a PDA. Data is entered by selecting allowed values from pop-up menus, dragging sliders around and checking boxes. The software we chose was Pendragon® Forms. The result is a structured and fast workflow, because the order in which the checks are performed is given by the form the user has to fill out on the PDA.

The forms are designed on the PC, frozen and send to the PDA, where data can be entered. The screenshot shows the design phase:

The forms design is intuitive and easy to learn. |

In the treatment room, the PDA is the ideal partner. First of all, it tells you what to do (which is a pleasant thing during routine checks). The values which are selectable in pop-ups at the same time define the allowed range for the measured parameter. To avoid handwriting on the screen (the handwriting recognition is much better but still not perfect), all results are entered by checkboxes, pop-ups and sliders.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

| ... and so on. Similar forms are implemented for our Simulator. Forms are only designed for checks which require data entry in the treatment room. |  |

|

When the form is completed, the PDA is docked on a cradle and data is synchronized with the Access database on the server, "merging" dosimetric and mechanical data by forming a comprehensive two-page protocol for this check, which is printed on a duplex-color-laser-printer, producing only one sheet of paper. In old days of hand-written protocols, we had 4 sheets for the same check!

|

|

Front

side of printout - mechanical checks |

Back

side of printout - dose measurements |