During operation, DAVID measures its own temperature continuously with an internal temperature sensor. Together with a user-given pressure value, the DAVID software then corrects the dose measurements for changes in air density (with respect to the last calibration dose measurement).

We wanted to find out how accurate the internal temperature sensor is. For comparison, we used a calibrated two-channel Fluke Hart Scientific "DewK" and a calibrated single-channel Fluke Hart Scientific "1504" thermometer. The DewK also measures humidity, but we ignore this. The accuracy of the DewK ("S" Model) is ±0.25°C, the 1504 is described here.

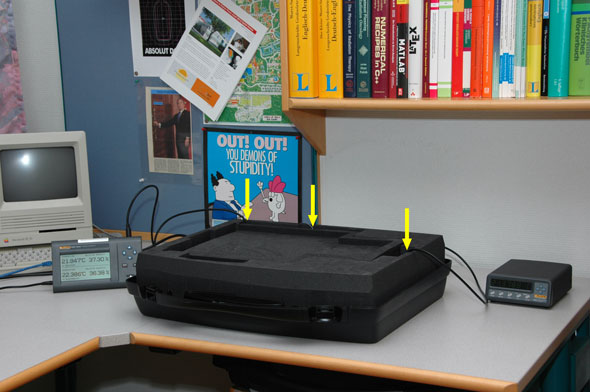

The following two photos show the setup (click to enlarge). The original DAVID case, without top cover, gives a fairly good temperature bath. The room was at constant temperature, with no extra heating or air turbulences. DAVID was switched on in the morning and then left in the case the whole day, where it was measuring continuously for about seven hours (until the battery was empty). The measurement was only interrupted briefly from time to time to read internal temperature via an attempted calibration measurement (this opens a window where the actual internal temperature is displayed).

On the following photo, the yellow arrows point to the locations where the three temperature sensor cables enter the case:

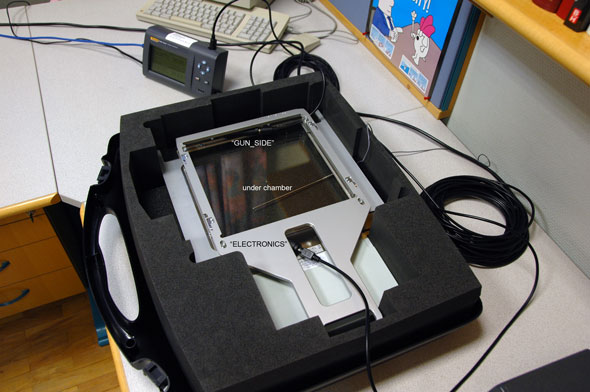

The open case (after removal of the foam filling) shows the exact placement of the sensors:

The two DewK sensors are placed above the ionization chamber, one on the gun side edge ("GUN_SIDE"), the other close to the interface between chamber and electronics ("ELECTRONICS"). The long 5610 thermistor probe of the Hart 1504 is placed directly under the chamber. It is in contact with the lower chamber window.

Results

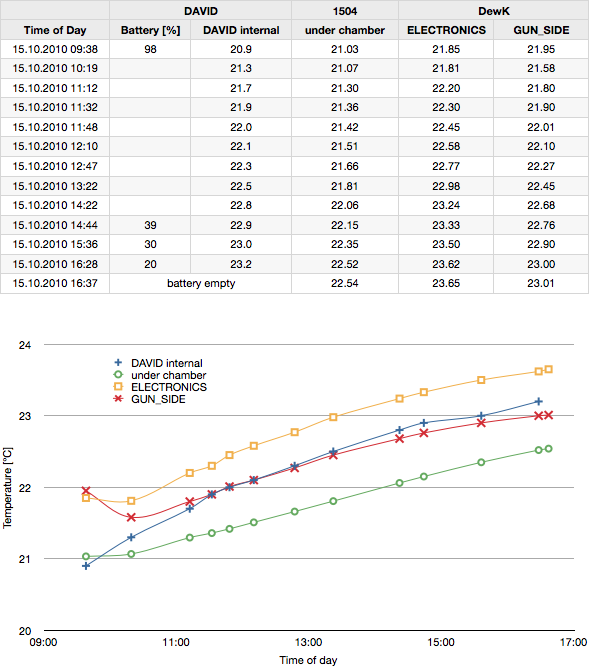

The following chart and graph show the four temperature sensor readings as a function of time. DAVID was switched on at 9:10 a.m. At 9:12, a zero measurement was performed. Battery level decreased linearly during the day (the battery had been charged over night). At 16:37, DAVID software declared the battery "empty" and stopped operation. (Note: this battery had only two full charge cycles at the time of the experiment, so the maximum capacity was probably not yet reached.)

After some thermal stabilization of the system, temperature values increased continuously over the day. This probably comes from the heat dissipated by the battery. The internal temperature value is always higher than the temperature measured under the lower chamber window (this temperature is always lowest) and lower than the reading of the sensor close to electronics. Both seems plausible: warm air goes up, and electronics contains an energy source (the battery).

Summary

From this desktop experiment under (more or less) thermal equilibrium, there is no reason not to trust the temperature values reported by DAVID. The sensor seems to be more accurate than it needs to be, since all measurements are relative to a calibration measurement (40 x 40 cm field) which is usually performed in the morning.

However, when DAVID is installed at the linac, the machine's head is usually warmer than the surrounding treatment room, and conditions are different. The system is hardly ever in thermal equilibrium. Heat flows from the warm linac to DAVID mainly via heat conduction over the connecting frame. If DAVID is taken out of a storage room, attached to the linac and the calibration is performed too early, a dose error might still be introduced, because the internal temperature sensor, no matter where it is placed, can never represent the whole chamber volume under conditions of thermal disequilibrium. Therefore it is probably a good idea to repeat the calibration measurement several times during the day.